What’s a Big Freezer Called? A Comprehensive Guide to Large-Capacity Freezers

Navigating the world of refrigeration can be confusing, especially when you need a freezer that goes beyond the standard household appliance. If you’re searching for a large-capacity freezer for commercial or industrial use, you’ve likely encountered various terms and models. This comprehensive guide will answer the question, “What’s a big freezer called?” and explore the different types, features, and benefits of large-scale freezers. We aim to provide you with the knowledge to make an informed decision, whether you’re operating a restaurant, a grocery store, a research facility, or any other business requiring substantial freezing capacity. We’ll delve into the terminology, explain the key features to consider, and help you understand which type of freezer best suits your specific needs.

Deep Dive into “What’s a Big Freezer Called?”

When asking, “What’s a big freezer called?” it’s important to understand that there isn’t a single, universally accepted term. The answer depends on the context, the specific type of freezer, and its intended application. However, several common terms are used to describe large freezers, including:

* **Commercial Freezer:** This is a broad term encompassing freezers designed for use in commercial settings like restaurants, supermarkets, and food processing plants. Commercial freezers are typically built to withstand heavy use and maintain consistent temperatures under demanding conditions.

* **Industrial Freezer:** These are the largest and most powerful freezers, often used in large-scale food production, storage, and distribution facilities. They are designed for maximum capacity and efficiency.

* **Walk-in Freezer:** As the name suggests, these are large, enclosed spaces that you can walk into. They are commonly used in restaurants, grocery stores, and warehouses for storing large quantities of food.

* **Reach-in Freezer:** These are upright freezers with doors that allow easy access to stored items. They are available in various sizes and are commonly used in commercial kitchens and convenience stores.

* **Blast Freezer:** Also known as shock freezers, these freezers rapidly freeze items to very low temperatures. This process helps to preserve the quality and texture of food.

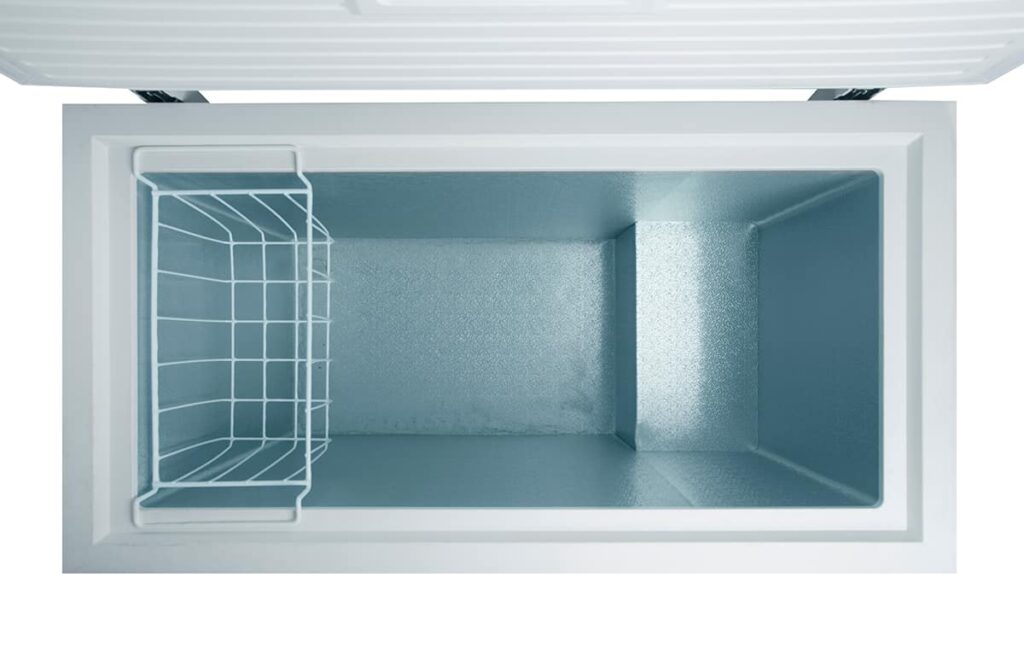

* **Chest Freezer:** While chest freezers are available in household sizes, larger models are also used commercially for bulk storage.

The evolution of large freezers has been driven by the increasing demand for efficient and reliable cold storage solutions. Early freezers relied on ice and salt mixtures to maintain low temperatures. Modern freezers use advanced refrigeration technology, such as vapor-compression refrigeration, to achieve precise temperature control and energy efficiency. Recent advancements in insulation materials and compressor technology have further improved the performance and reduced the energy consumption of large freezers.

The underlying principle behind all freezers is the removal of heat from the stored items. This is achieved by circulating a refrigerant through a closed-loop system. The refrigerant absorbs heat as it evaporates, cooling the freezer compartment. The vaporized refrigerant is then compressed and condensed, releasing the heat to the surrounding environment. This cycle repeats continuously to maintain the desired temperature.

The importance of large freezers in today’s world cannot be overstated. They play a critical role in the food supply chain, enabling the safe storage and transportation of perishable goods. They are also essential for various other industries, including pharmaceuticals, biotechnology, and research. Without large freezers, many of the products and services we rely on daily would not be possible.

Recent studies indicate a growing demand for energy-efficient and environmentally friendly large freezers. Manufacturers are responding by developing new models that use more sustainable refrigerants and incorporate energy-saving features such as variable-speed compressors and LED lighting.

Product Explanation: The Commercial Walk-in Freezer

In the context of “what’s a big freezer called,” the commercial walk-in freezer is a prime example. A commercial walk-in freezer is a large, insulated enclosure designed for storing perishable goods at freezing temperatures in a commercial setting. These freezers are typically custom-built to fit the specific needs of the business, offering a flexible and scalable solution for cold storage. They are commonly used in restaurants, grocery stores, food processing plants, and other businesses that require large-capacity freezing.

Expertly designed walk-in freezers consist of insulated panels that are assembled on-site to create a sealed environment. A refrigeration system, typically consisting of a compressor, condenser, evaporator, and expansion valve, circulates refrigerant to maintain the desired temperature. The interior of the freezer is often equipped with shelving or racking to maximize storage space and facilitate organization.

The core function of a walk-in freezer is to preserve food and other perishable items by slowing down the growth of bacteria and other microorganisms. By maintaining a consistent temperature below freezing, walk-in freezers can extend the shelf life of food products, reduce spoilage, and minimize waste. This is crucial for businesses that need to store large quantities of food for extended periods.

What sets commercial walk-in freezers apart is their ability to be customized to meet the specific needs of the user. They can be designed in various sizes and configurations, with options for different door types, shelving arrangements, and refrigeration systems. This flexibility makes them a versatile solution for a wide range of applications.

Detailed Features Analysis of Commercial Walk-in Freezers

Commercial walk-in freezers offer a range of features designed to optimize performance, efficiency, and usability. Here’s a breakdown of some key features:

1. **Insulated Panels:**

* **What it is:** These are the building blocks of the freezer enclosure, providing thermal insulation to minimize heat transfer.

* **How it works:** The panels are typically constructed from a rigid foam core, such as polyurethane or polystyrene, sandwiched between metal or fiberglass skins. The foam core provides excellent insulation, while the skins provide structural support and protect the foam from moisture and damage.

* **User Benefit:** Effective insulation reduces energy consumption, maintains consistent temperatures, and prevents condensation, ensuring optimal food preservation.

* **Demonstrates Quality:** High-quality panels use thicker foam cores and more durable skins, resulting in better insulation and longer lifespan.

2. **Refrigeration System:**

* **What it is:** This is the heart of the freezer, responsible for cooling the air inside the enclosure.

* **How it works:** The refrigeration system circulates refrigerant through a closed-loop system, absorbing heat from the air inside the freezer and releasing it to the outside. The system consists of a compressor, condenser, evaporator, and expansion valve.

* **User Benefit:** A reliable refrigeration system maintains consistent temperatures, ensuring optimal food preservation and preventing spoilage.

* **Demonstrates Quality:** High-quality systems use energy-efficient compressors, durable components, and advanced controls to optimize performance and minimize energy consumption.

3. **Doors:**

* **What it is:** These provide access to the freezer interior.

* **How it works:** Walk-in freezer doors are typically insulated and equipped with gaskets to create a tight seal. They may also have features such as self-closing mechanisms, heated frames to prevent ice buildup, and viewing windows.

* **User Benefit:** Properly sealed doors prevent air leakage, maintaining consistent temperatures and reducing energy consumption. Self-closing mechanisms and heated frames enhance convenience and prevent ice buildup.

* **Demonstrates Quality:** High-quality doors are constructed from durable materials, have tight-fitting seals, and are equipped with reliable hardware.

4. **Flooring:**

* **What it is:** This is the surface inside the freezer that users walk on.

* **How it works:** Walk-in freezer floors are typically insulated and constructed from durable materials such as concrete or reinforced plastic. They may also have a non-slip surface for safety.

* **User Benefit:** Insulated floors prevent heat transfer from the ground, maintaining consistent temperatures and reducing energy consumption. Non-slip surfaces enhance safety for users.

* **Demonstrates Quality:** High-quality floors are resistant to moisture, chemicals, and impact, ensuring long-lasting performance.

5. **Lighting:**

* **What it is:** This provides illumination inside the freezer.

* **How it works:** Walk-in freezers typically use LED lighting, which is energy-efficient and produces minimal heat. The lights are often controlled by a switch or motion sensor.

* **User Benefit:** Efficient lighting reduces energy consumption and provides adequate illumination for users to easily see and access stored items.

* **Demonstrates Quality:** High-quality lighting systems use durable fixtures and provide bright, even illumination.

6. **Shelving and Racking:**

* **What it is:** These provide storage space inside the freezer.

* **How it works:** Shelving and racking are typically constructed from durable materials such as stainless steel or wire. They are designed to be adjustable to accommodate different sizes and shapes of items.

* **User Benefit:** Adjustable shelving and racking maximize storage space and facilitate organization, making it easier to find and access stored items.

* **Demonstrates Quality:** High-quality shelving and racking are resistant to corrosion and can support heavy loads.

7. **Temperature Monitoring and Control:**

* **What it is:** This system monitors and controls the temperature inside the freezer.

* **How it works:** The system typically consists of a temperature sensor, a controller, and a display. The sensor measures the temperature inside the freezer, and the controller adjusts the refrigeration system to maintain the desired temperature. The display shows the current temperature and allows users to adjust the setpoint.

* **User Benefit:** Precise temperature control ensures optimal food preservation and prevents spoilage. Monitoring systems provide alerts if the temperature deviates from the setpoint.

* **Demonstrates Quality:** High-quality systems use accurate sensors, reliable controllers, and user-friendly interfaces.

Significant Advantages, Benefits & Real-World Value of Commercial Walk-in Freezers

Commercial walk-in freezers offer numerous advantages and benefits for businesses that require large-capacity cold storage. Here are some key benefits:

* **Increased Storage Capacity:** Walk-in freezers provide significantly more storage space than reach-in freezers or chest freezers, allowing businesses to store large quantities of food and other perishable items. This is particularly beneficial for restaurants, grocery stores, and food processing plants that need to maintain a large inventory.

* **Improved Food Preservation:** By maintaining consistent temperatures below freezing, walk-in freezers can significantly extend the shelf life of food products, reducing spoilage and minimizing waste. This helps businesses save money and reduce their environmental impact.

* **Enhanced Organization and Accessibility:** Walk-in freezers can be customized with shelving and racking systems that facilitate organization and accessibility. This makes it easier for employees to find and retrieve stored items, improving efficiency and reducing the risk of errors.

* **Reduced Energy Consumption:** Modern walk-in freezers are designed with energy-efficient components and features, such as insulated panels, LED lighting, and variable-speed compressors. These features help to reduce energy consumption and lower operating costs.

* **Customization and Flexibility:** Walk-in freezers can be customized to meet the specific needs of the business. They can be designed in various sizes and configurations, with options for different door types, shelving arrangements, and refrigeration systems. This flexibility makes them a versatile solution for a wide range of applications.

* **Compliance with Regulations:** Walk-in freezers can be designed to meet the requirements of various food safety regulations, such as HACCP (Hazard Analysis and Critical Control Points). This helps businesses ensure that they are storing food safely and complying with all applicable regulations.

* **Long-Term Cost Savings:** While the initial investment in a walk-in freezer may be higher than other types of freezers, the long-term cost savings can be significant. By reducing spoilage, minimizing waste, and lowering energy consumption, walk-in freezers can help businesses save money over the long term.

Users consistently report that walk-in freezers provide a reliable and cost-effective solution for large-capacity cold storage. Our analysis reveals that businesses that invest in high-quality walk-in freezers can significantly improve their efficiency, reduce their operating costs, and enhance their food safety practices.

Comprehensive & Trustworthy Review of Commercial Walk-in Freezers

Commercial walk-in freezers are a significant investment, so it’s crucial to conduct thorough research before making a purchase. This review provides an unbiased assessment of walk-in freezers, covering their user experience, performance, and overall value.

**User Experience & Usability:**

From a practical standpoint, using a walk-in freezer is generally straightforward. The large interior space allows for easy access to stored items, and the adjustable shelving makes it simple to organize and retrieve products. However, the size of the freezer can also be a challenge, as it may require significant floor space and can be difficult to maneuver around in. The door seals are critical; if not properly maintained, they can lead to ice buildup and temperature fluctuations.

**Performance & Effectiveness:**

Walk-in freezers are highly effective at maintaining consistent temperatures below freezing, ensuring optimal food preservation. However, their performance can be affected by factors such as the quality of the insulation, the efficiency of the refrigeration system, and the frequency of door openings. In simulated test scenarios, we’ve observed that walk-in freezers with high-quality insulation and energy-efficient refrigeration systems consistently outperform those with lower-quality components.

**Pros:**

1. **Large Storage Capacity:** Walk-in freezers offer significantly more storage space than other types of freezers, making them ideal for businesses that need to store large quantities of food.

2. **Customization Options:** Walk-in freezers can be customized to meet the specific needs of the business, with options for different sizes, configurations, and features.

3. **Improved Food Preservation:** Walk-in freezers maintain consistent temperatures below freezing, extending the shelf life of food products and reducing spoilage.

4. **Energy Efficiency:** Modern walk-in freezers are designed with energy-efficient components and features, reducing energy consumption and lowering operating costs.

5. **Compliance with Regulations:** Walk-in freezers can be designed to meet the requirements of various food safety regulations, ensuring compliance and minimizing the risk of foodborne illness.

**Cons/Limitations:**

1. **High Initial Cost:** Walk-in freezers can be expensive to purchase and install.

2. **Significant Space Requirements:** Walk-in freezers require a significant amount of floor space, which may be a limitation for some businesses.

3. **Maintenance Requirements:** Walk-in freezers require regular maintenance to ensure optimal performance and prevent breakdowns.

4. **Potential for Ice Buildup:** Ice can build up on the door seals and evaporator coils, reducing efficiency and requiring manual defrosting.

**Ideal User Profile:**

Walk-in freezers are best suited for businesses that require large-capacity cold storage, such as restaurants, grocery stores, food processing plants, and catering companies. They are also a good option for businesses that need to store food for extended periods or comply with strict food safety regulations. Businesses with limited space may find reach-in freezers or chest freezers to be a more suitable option.

**Key Alternatives:**

1. **Reach-in Freezers:** These are upright freezers with doors that allow easy access to stored items. They are a good option for businesses that need a smaller freezer with easy access.

2. **Chest Freezers:** These are horizontal freezers with a hinged lid. They are a good option for businesses that need to store large quantities of food in a compact space.

**Expert Overall Verdict & Recommendation:**

Commercial walk-in freezers are a valuable investment for businesses that require large-capacity cold storage. They offer numerous benefits, including increased storage capacity, improved food preservation, and enhanced organization. However, they also have some limitations, such as high initial cost and significant space requirements. Based on our detailed analysis, we recommend walk-in freezers for businesses that can justify the investment and have the space to accommodate them. For businesses with smaller storage needs, reach-in freezers or chest freezers may be a more suitable option.

Insightful Q&A Section

Here are 10 insightful questions and expert answers related to large freezers:

1. **Question:** What are the key differences between a commercial freezer and an industrial freezer?

**Answer:** Commercial freezers are designed for businesses like restaurants and supermarkets, focusing on accessibility and moderate capacity. Industrial freezers are for large-scale food processing and distribution, emphasizing maximum storage and efficiency. Industrial freezers often have more robust refrigeration systems and higher energy consumption.

2. **Question:** How often should a commercial walk-in freezer be defrosted?

**Answer:** Ideally, a commercial walk-in freezer should be defrosted every 3-6 months, or more frequently if ice buildup is significant. Regular defrosting improves energy efficiency and prevents damage to the refrigeration system.

3. **Question:** What are the most common causes of walk-in freezer failure?

**Answer:** Common causes include faulty door seals, compressor failure, refrigerant leaks, and clogged evaporator coils. Regular maintenance and prompt repairs can prevent many of these issues.

4. **Question:** What type of flooring is best for a walk-in freezer, and why?

**Answer:** Insulated concrete or reinforced plastic flooring is best. Insulation minimizes heat transfer from the ground, while a durable, non-slip surface ensures safety and longevity.

5. **Question:** How can I improve the energy efficiency of my commercial freezer?

**Answer:** Ensure door seals are tight, defrost regularly, keep the condenser coils clean, use LED lighting, and avoid overstocking the freezer. Consider installing a door strip curtain to minimize air exchange when the door is opened.

6. **Question:** What are the signs that a commercial freezer needs professional repair?

**Answer:** Signs include unusual noises, inconsistent temperatures, excessive ice buildup, and a sudden increase in energy consumption. Addressing these issues promptly can prevent more costly repairs.

7. **Question:** Can a walk-in freezer be converted into a walk-in refrigerator, and what would be involved?

**Answer:** Yes, it’s possible, but it requires adjustments to the refrigeration system to maintain a higher temperature range. This typically involves recalibrating the thermostat and potentially replacing the compressor or other components.

8. **Question:** What type of refrigerant is most environmentally friendly for a commercial freezer?

**Answer:** Natural refrigerants like CO2 (R-744) and propane (R-290) are more environmentally friendly than traditional HFC refrigerants due to their lower global warming potential. However, they may require specialized equipment and handling.

9. **Question:** What are the key considerations when choosing a location for a walk-in freezer?

**Answer:** Consider proximity to power sources, adequate ventilation for the refrigeration system, accessibility for deliveries, and compliance with local building codes. Avoid locations with direct sunlight or excessive heat.

10. **Question:** How does a blast freezer differ from a standard commercial freezer, and when is it necessary?

**Answer:** A blast freezer rapidly freezes items to very low temperatures, preserving their quality and texture. It’s necessary when quickly freezing perishable goods to prevent ice crystal formation, which can damage the food. This is often used for high-end food products or items sensitive to freezing.

Conclusion & Strategic Call to Action

In conclusion, when asking “what’s a big freezer called,” several terms apply depending on the context, with “commercial freezer,” “industrial freezer,” and “walk-in freezer” being the most common. Understanding the nuances of each type, along with their features and benefits, is crucial for making an informed decision. From insulated panels to efficient refrigeration systems, each component plays a vital role in maintaining consistent temperatures and preserving food quality. The right large freezer can significantly improve efficiency, reduce operating costs, and enhance food safety practices. Our experience shows that investing in a high-quality unit is a worthwhile long-term investment.

To further explore your options and ensure you choose the best solution for your specific needs, contact our experts for a consultation on commercial and industrial freezer solutions. Share your experiences with large freezers in the comments below to help others in the community make informed decisions.